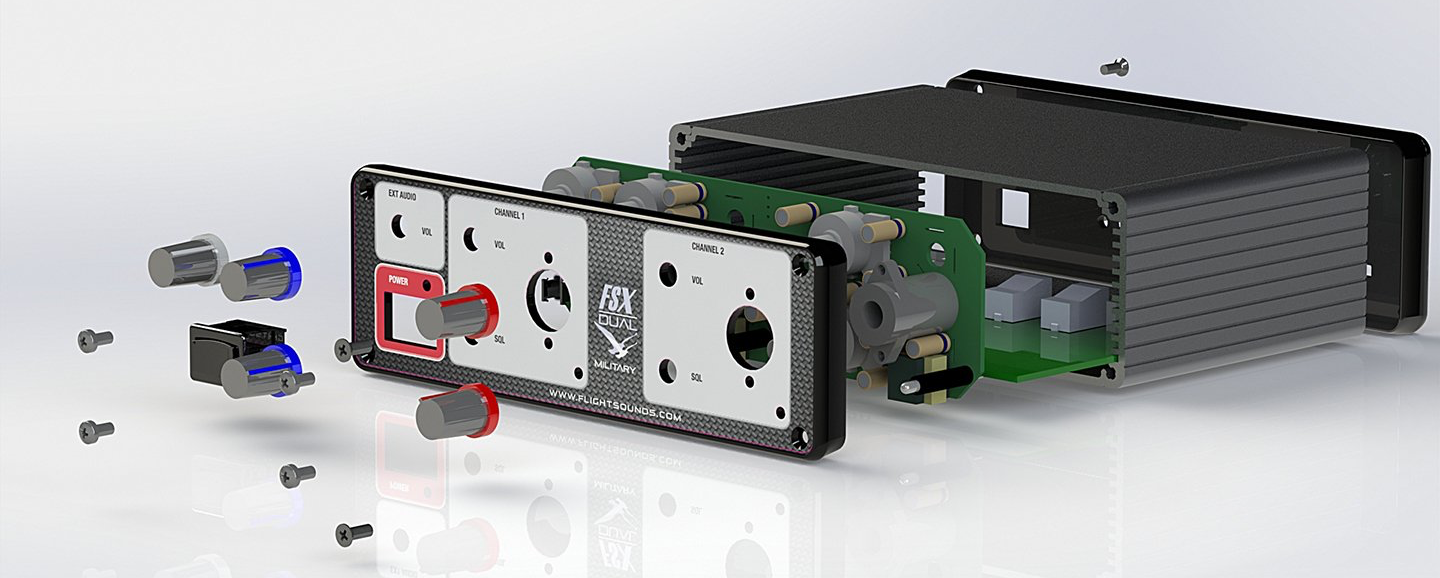

Aviation Audio USB Adapter

(Photo credit: Flight Sounds Ltd)

Opportunity

Real-world aviation (flying) is expensive! It is well known that Flight Simulation software enables Pilots to maximise their proficiency, thereby reducing flying training hours and therefore cost. While most Pilots own their own headsets, it was found that no satisfactory products existed, which could seamlessly connect a genuine aviation headset to a modern computer. Hence, the Flight Sounds company was formed.

Flight Sounds needed a product designed with the following requirements:

- Allow users to easily interface their real-world aviation headsets to any modern PC.

- Closely match the audio intercom and radio features found in actual aircraft cockpits.

- Be a functionally robust, aesthetically pleasing, and high quality product.

- Have the ability to be effortlessly manufactured in high volumes.

Flight Sounds looked no further than to partner with Beta Solutions, due to its proven experience in hi-tech electronics (including audio electronics) and electro-mechanical product development.

Solution

While many off-the-shelf headset adapters exist on the market, they are not able

to work with the specific characteristics of Aircraft Headsets. Aviation headsets generally require audio devices capable of significant "driving power" in order to drive their high impedance headphones to an acceptable volume. Additionally, Aviation headsets often incorporate electret microphones, which require much higher voltages to operate than standard (e.g.: gaming) headset microphones. Further, off-the-shelf adapters would also not be capable of incorporating the other advanced features that Flight Sounds required - such as Volume and Squelch level controls, Push to Talk, Intercom functionality and external audio inputs.

Therefore, it was apparent that a custom electronics solution was needed.

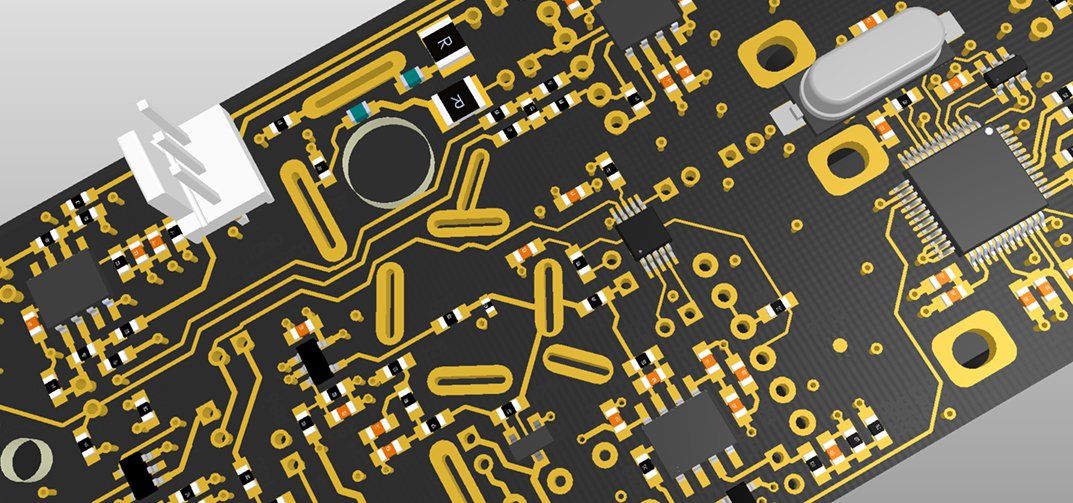

Electronic Design Aspects

As the device was to be as easy as possible to use, we designed the electronics in such a way that the entire device functioned as a custom-built external USB sound card. The users could simply plug the product into an available USB port, and the computer's "auto-detection" would do the rest - no complicated software, no need for additional power cables, no potential for mixing up (analogue) mic and headset connectors - just plug and play!

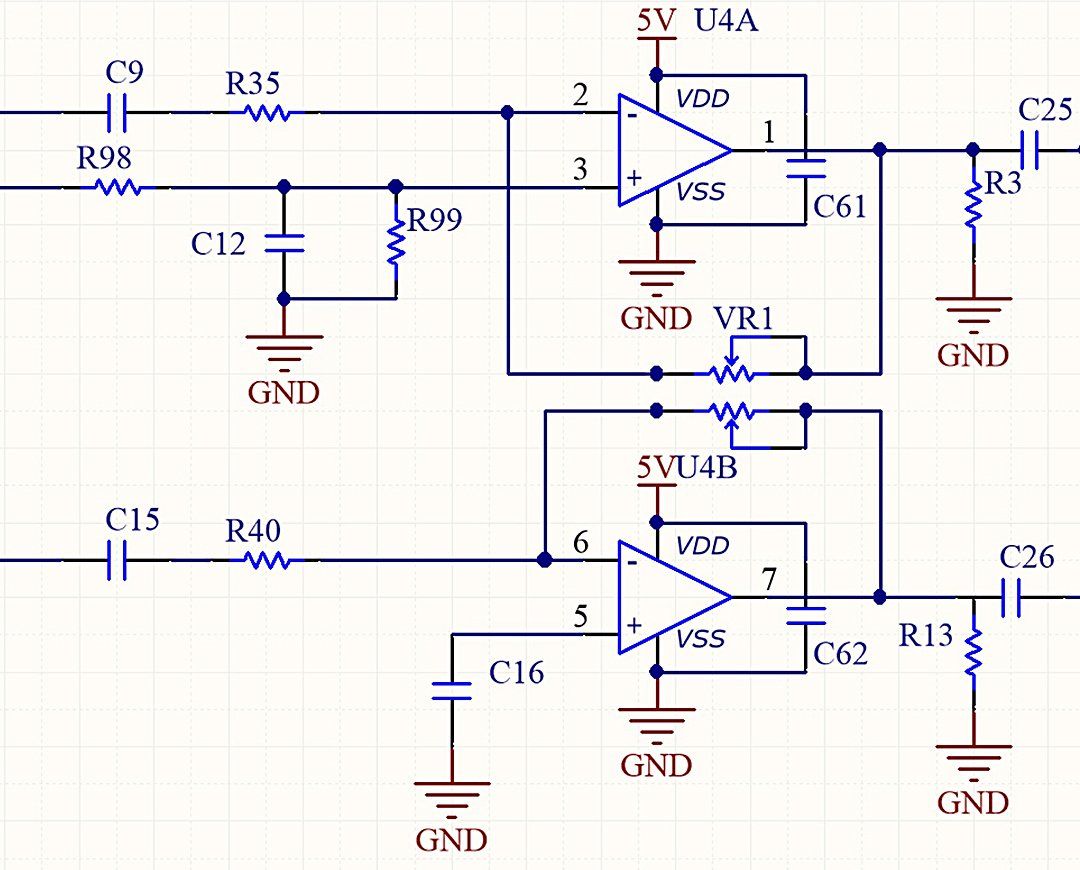

The electronics contained the following componentry:

- USB audio device

- Converts the audio to/from digital/analogue

- Headphones power amplifier

- Drives the high impedance headphones with enough power

- Power supply microphone bias circuitry

- Enables operation of the aviation electret microphones (+9Vdc)

- Microphone "auto-detection" circuitry (Military model only)

- Contains a complex array of circuitry to automatically detect between electret microphones and low impedance dynamic mics. NB: The circuitry has to boost the tiny (dynamic) microphone signal more than x6,000 times (75dB)

- Specialist aviation connectors

- Permits connection to both (twin connector) "General Aviation" Headsets and also (single connector) "Helicopter" headsets

Mechanical Design Aspects

In order to meet the objective of constructing a quality product, we enclosed the electronics in an extruded aluminium enclosure. Aluminium is a robust metal (including being largely resistant to corrosion), while also being relatively

light-weight - an important cost savings attribute if the product is intended to be air freighted around the world.

The PCB and enclosure were both carefully modelled using Solidworks CAD software, which provided confidence that every component would fit together correctly, prior to producing the prototypes.

The product is designed in such a way that the circuit board and connectors do not carry any direct mechanical load. That is, the mechanical enclosure takes all of the push/pull and side-to-side stresses placed on the connectors.

Design Validation

It is almost always more cost effective (in the long run) to invest in designing any product "right" the first time, rather than releasing inadequately tested products to the market, only to experience product failures at a later date.

It was important to both Flight Sounds and us to undertake thorough design validation testing, before any product was sold to paying customers. This involved testing aspects such as electromagnetic interference (EMI), power supply integrity, USB protocol conformance, headset compatibility, human factors usability and audio signal to noise (SNR) properties.

Success

Beta Solutions is proud to have met Flight Sounds' original goal of transforming a concept idea into a commercial product. Flight Sounds is selling thousands of products, shipped all over the world, supplying companies who make simulators, pilot schools, and home simulation users wanting to improve their simulation experience. You can visit http://flightsounds.com/ to see the extended range of products developed.

Flight Sounds Customer's Testimonial

"This thing is PERFECT. I ordered it, and not much later it arrived at my door. Within 30 seconds (literally) I was using it. It just worked. No software to install; no messing with my existing audio cables; just plug it in, plug in my headset, and start talking."

David B (USA)

(Photo credit: Flight Sounds Ltd)

* All the content in this article, including imagery, has been approved by our client for publication on this website.