Dedicated to exceed

Innovation with integrity and purpose.

Button

Dedicated to exceed

Innovation with integrity and purpose.

Button

Dedicated to exceed

Innovation with integrity and purpose.

Button

Dedicated to exceed

Innovation with integrity and purpose.

Button

Dedicated to exceed

Innovation with integrity and purpose.

Empowering our clients with innovative technology to help them build a better future for themselves, their employees, and New Zealand, is the reason why we cannot wait to get to work everyday.

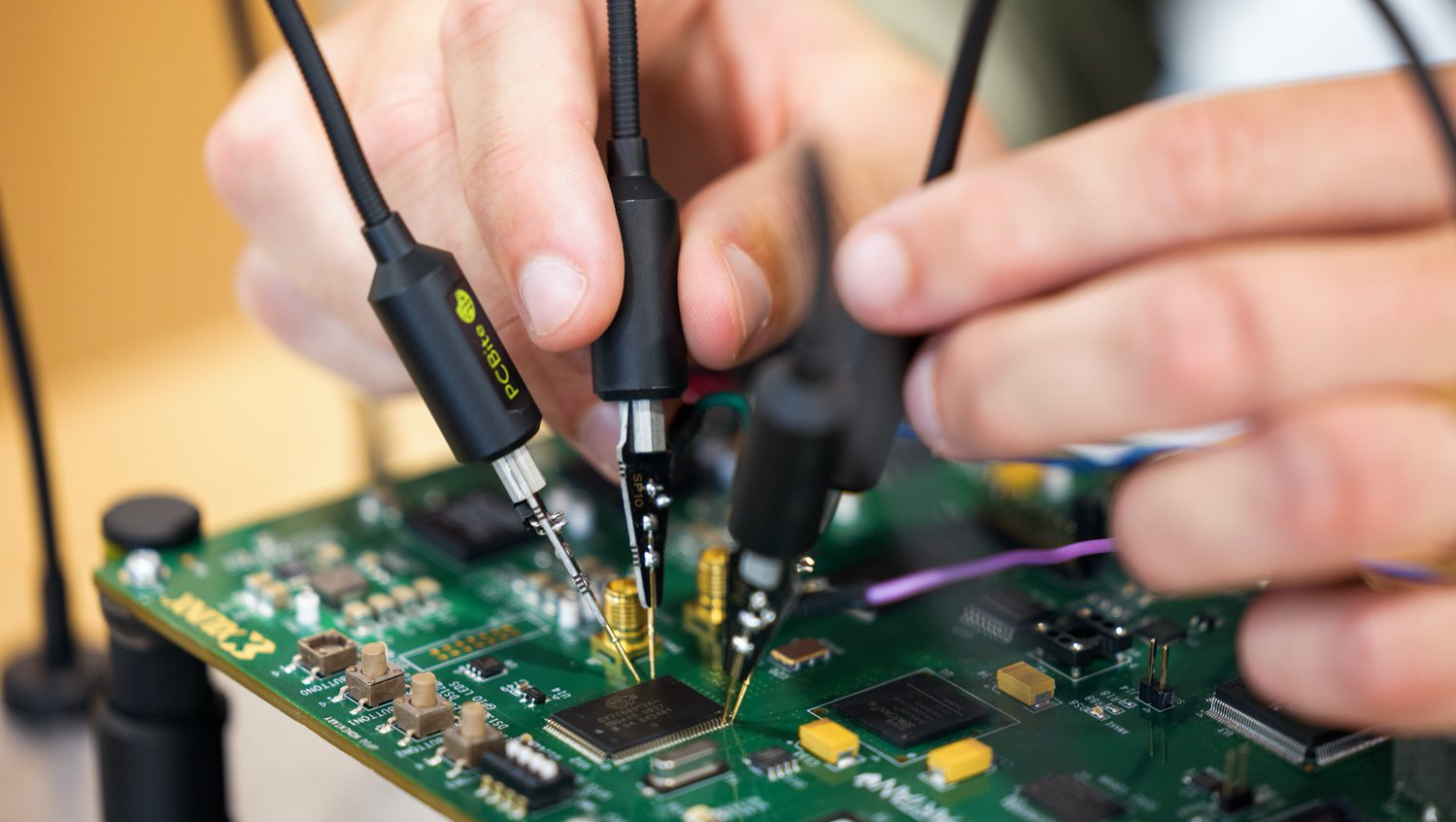

Our clients' privacy and the protection of their intellectual property is a non-negotiable for us. Therefore, we cannot always share the exciting electronics projects we work on. Thank you to these clients below, who have granted us permission to share the innovation projects that we have developed with them.

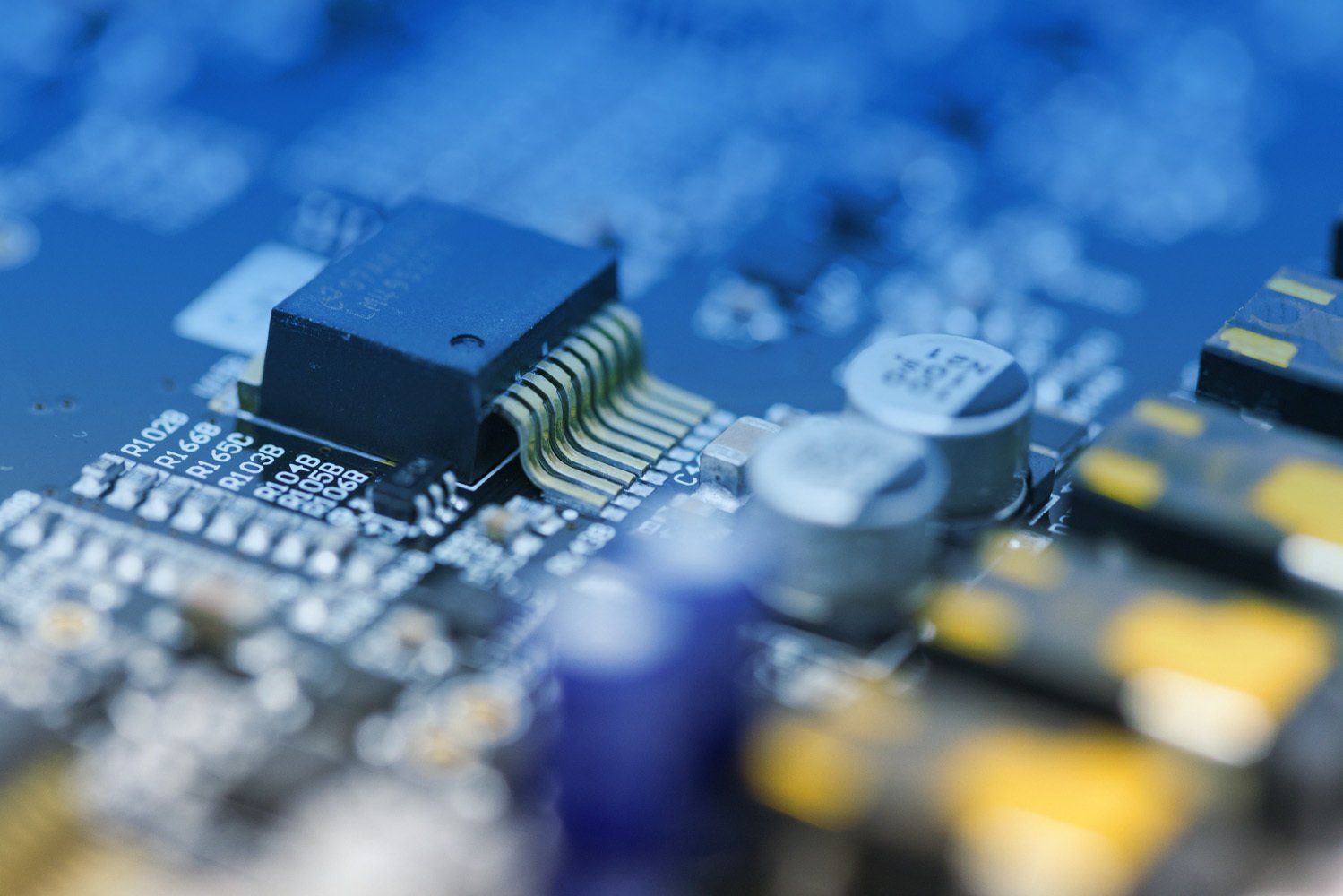

Explore a selection of electronics design projects.

Over the past decade, Beta Solutions has proudly partnered with Thermoplastic Engineering (TPE), working hand-in-hand to create cutting-edge control solutions for their state-of-the-art fume cupboards.As time progressed, the demands for these fume cupboards have evolved, necessitating the integration of diverse controllers and numerous custom adjustments to deliver a truly tailored experience for each client.

Beta Solutions partnered with Atkinson & Rapley Consulting Ltd, designing a dual-channel, broad-spectrum, USB sound recording device for recording environmental sound, specifically for investigating industrial noise pollution. The low noise specifications were very strict, but the end result surpassed expectations.

Low Noise USB Audio Device

Anyone who has experienced being shocked by a several thousand volt Electric Fence knows it hurts - really hurts! Daniel Hall envisaged it should be possible to implement some "smart technology" - harnessing the power of a modern smart phone - to detect whether the fence was on or off. With that in mind, Dan engaged Beta Solutions to assist with the development. What resulted was a product which won the Vodafone Innovation in Technology Award at the National Fieldays at Mystery Creek in 2015.

Ravensdown partnered with Beta Solutions to develop a highly specialised Lightbar display, which is now used to guide Aerowork pilots during aerial topdressing operations. Aerowork is the largest aerial fertiliser applicator in New Zealand, and with a history stretching back over 60 years, its also the most experienced aerial spreader in New Zealand.

The development of this custom avionics tool was part of Ravensdown's continuous effort to improve the safety and effectiveness of its application operations.

Gloworm Performance Products is a world leader in bike and adventure lighting with its series of high quality, high performance, LED lighting systems. Gloworm engaged Beta Solutions to help undertake aspects of the R&D to bring to life its vision for its new G2.0 lighting products.

Award-winning OMEO is the only personal mobility device that fully integrates a unique Active Seat Control system with the very best of self-balancing technology. Omeo partnered with Beta Solutions, particularly for the specialist electronic design skills required, to develop the self-balancing mobility vehicle.

OMEO Technology

Rinnai is synonymous with innovative heating solutions, providing customers with advanced technology designed for efficiency and reliability. As they ventured into their new project - the HydraHeat™ Hot Water Heat Pump - Rinnai turned to our expertise to develop an electronic control system refined for performance. We worked closely with Rinnai to create a control system harnessing the efficiency of heat pump technology, with estimations of up to 75% savings on hot water costs*.

Fonterra, known for being a world-leader in dairy, partnered with us to work with its in-house science team to design, build, and test a system to measure particular aspects of milk powder quality.

The project involved close collaboration with Fonterra science staff, with many site visits across the duration of the project to ensure the quality and reliability of developed systems. Read about the work we did together.

Flight Sounds Ltd looked to Beta Solutions to provide expert electronic design skills to help transform product concept ideas into a commercial reality. The products are specifically developed to enable pilots to interface their real-world aviation headsets to computers, and are intended to closely match the audio intercom and radio features found in actual aircraft cockpits. Flight Sounds has gone on to sell thousands of products to users all around the world.

BioLumic Ltd is a pioneer in developing world leading UV light solutions for the purposes of improving the yield, quality and disease resistance of crops. BioLumic products are a result of over 10 years of pioneering science and research in Ultra Violet (UV) Light and plant interactions.

Biolumic turned to Beta Solutions to help turn its scientific research into tangible products.

Resene Paints Ltd, NZ’s largest paint company, approached Beta Solutions with a view to help transform its idea into a commercial reality. Resene had a vision for a product which would enable users to control electrical devices (e.g.: house lights), simply by touching specially painted surfaces. These surfaces would be coated in the newly developed touch sensitive conductive paint and connected to some intelligent electronics.

Resene Smart Switch

“Spidertracks have been impressed with the capability and delivery of Beta Solutions. We were under significant time constraints, and also had to deal with variations in the product specification. Beta Solutions showed the ability to both identify future problems and to pro-actively provide alternative resolutions. Their ability to work in a flexible and interactive manner allowed the final design to be optimised. At several times the project came under extreme time pressure, and Beta were able to ramp up their delivery to match a very challenging deadline..."

Beta Solutions’ knowledge of forefront technology enabled our research to be translated into (components of) scientific instrumentation whose design and performance was comparable with the market leaders.

Dr Robin Dykstra - Senior Lecturer, School of Engineering | Victoria University (Wellington)

See why our clients chose us

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

-

Beta Solutions continue to impress. They have completed a number of projects for us over the years and Beta Solutions deliver on time and on schedule, every time. They have a broad skill base with unmatched expertise. The quality of their work, from design to documentation, is excellent. I highly recommend you contact them first if you care about quality, innovation, cost and performance.

Iannick Monfils, PhD - VP Engineering | Quantifi Photonics (Auckland) -

Beta Solutions were quick to translate our functional requirements into the technical specifications necessary for our prototype. Their technical capabilities were excellent, and we were very happy with the professionalism of their delivery. They achieved all of our requirements and provided full technical documentation to accompany the finished prototype.

Dr Andrew Coy - CEO | Magritek Ltd (Wellington) -

Beta Solutions’ knowledge of forefront technology enabled our research to be translated into (components of) scientific instrumentation whose design and performance was comparable with the market leaders. As an embedded electronic design partner, they were the perfect complement to our commitment to being world leaders in the field of NMR research and development.

Dr Robin Dykstra - Senior Lecturer, School of Engineering | Victoria University (Wellington) -

Beta Solutions provided 5th Element Ltd electronics design, PCB layout and testing services between August 2014 and October 2015. I was very impressed with Beta Solutions' communications, skill level and flexibility during this period. The project was halted several times by us for external reasons. Beta Solutions were happy to accommodate our timeline changes and other unreasonable requests as we shifted design goalposts during the program. I wouldn’t hesitate to recommend Beta Solutions Ltd to others. I think they have a particular flare in developing challenging designs for startup companies.

Mathew Jury - CTO | 5th Element Ltd (Lower Hutt) -

It is rare to find the combination of high-technology technical expertise, practical hands-on skills with sophisticated and friendly customer service, yet Beta Solutions has these. When we approached Beta Solutions to partner our product development, they were able to combine analog and digital design skills with a deep understanding of human interfacing that allowed them to design a stunning product from our technical brief. Beta Solutions project management skills and communication with the client has always been superb and any problems that surfaced were dealt with quickly and efficiently, and at the lowest possible cost to the client. Beta Solution’s combined talents are exemplary. That Beta Solutions have such a comprehensive team to focus on each project has meant that the overall R&D operation was smooth and effective from inception to finished product. The high-tech knowledge and state-of-the-art facilities make them a one-stop-shop for electronic product design and manufacture. Atkinson & Rapley Consulting cannot recommend them highly enough.

Dr Bruce Rapley - Principal Consultant | Atkinson & Rapley Consulting Ltd (Palmerston North) -

Spidertracks have been impressed with the capability and delivery of Beta Solutions. We were under significant time constraints, and also had to deal with variations in the product specification. Beta Solutions showed the ability to both identify future problems and to pro-actively provide alternative resolutions. Their ability to work in a flexible and interactive manner allowed the final design to be optimised. At several times the project came under extreme time pressure, and Beta were able to ramp up their delivery to match a very challenging deadline. Their project management skills and communications were appropriate and effective at all times. Beta solutions have contributed materially to the creation of our third generation spider unit, which is a "state of the Art" unit including a number of ground breaking technologies.

Mr Bruce Bartely - Director | SpiderTracks Ltd (Auckland) -

Deadlines don't wait. Working to stringent specifications, it took TPE, working with Beta Solutions Ltd, just under six months to design and produce a new controller EcoAir® III - which includes many new features not seen before in Australasia.

Simon Jones - Managing Director | Thermoplastic Engineering Ltd (Porirua) -

I cannot fault Terry and the team at Beta Solutions. I had no previous experience in product development and even less knowledge when it came to electronics. Everyone at Beta Solutions really took the time to explain each step and I really appreciate the up to date communication throughout the project. Deadlines were met and quotes were accurate. I would have no problem recommending Beta Solutions for any electronic engineering or product development. Thanks again to everyone at Beta Solutions.

Grant Clark - Owner | Broken Compass (Whakatane) -

We have worked with Beta Solutions for some years now. They have been responsible for the electronic firmware development of the Omeo. It has been a challenging task but they have always been up to the challenge. Beta have been willing to address any issues and come up with enhancements that we have required. It has been a real pleasure working with such competent, intelligent and highly qualified individuals. Always willing to do everything they can to meet our deadlines.

Mike Redman, CFO | OMEO Technology (Otaki) -

Beta Solutions transformed our vision from a concept into a result that was fully scalable and optimised for real-world application. From system design to development and testing, each step was clear, considered and well communicated. Equally impressive was their ability to research and adapt as technical challenges presented themselves. We look forward to continuing to build our capabilities together.

Simon Rycroft, Creative Director | Abstract Interactive Ltd (Christchurch) -

Approachable and willing to discuss options, Terry and the team at Beta Solutions provided an excellent service. They analysed the electronic problem I was having, identified the issue and quickly provided a solution. I'm very happy with the result. Many thanks.

Mark Krivan (Manawatu) -

I engaged Beta Solutions on through Auckland Museum to complete a bespoke circuit for us for one of our large scale, complex public interactives. The responses, level of contact and attention to detail were great and a massive effort was always made to ensure timeframes were met and within budget. The end results have proven to be perfect for us. Now in the final stages of mock-up testing we have continually been very happy with the result. Great team to work with and given the level of custom electronics we have the need for, we will definitely be back.

Liam Brown - Audio Visual Manager | Auckland Museum (Auckland)

Numbers that might interest you!

830+

Finished Projects

150+

CLIENTS

15+

YEARS

56+

TEAM Challenges