Electromagnetic Compatibility (EMC) Compliance - Answers to Frequently Asked Questions

Date: May 30, 2018

So you've got an idea for a brilliant new product that you want to develop and then put to market? And you've heard about this thing called 'EMC' but you don't know exactly what it is or why it should matter to you? Or how long will it take? Or how much will it cost? The purpose of this blog is to answer some of these questions and explain what 'EMC' is and why you really do need to know about it.

If you haven't already, please read our previous blog on compliance, Electronic Product Compliance - Answers to FAQs, which answers common questions our customers have had about complying with the regulations which govern electronic products here in NZ and abroad.

What is 'EMC'?

EMC or Electromagnetic Compatibility is a term which refers to how well electronic devices operate within the same vicinity without interfering with each other. A device which has poor Electromagnetic Compatibility could either cause problems with nearby devices or those same devices could cause it to have problems. You may have experienced this yourself if you ever used an older wireless home phone at the same time that a microwave oven is operating. The electromagnetic energy being emitted from a 'leaky' microwave oven can be detrimental to the audio quality on those old handsets. Wifi performance can also be slowed down or interrupted by 'leaky' microwave ovens or other wireless products like baby monitors or security cameras.

Almost all electronics emit at least some electromagnetic energy during their operation. This is just a consequence of using electrical energy. Given a high enough magnitude, almost all electronics can be susceptible to the energy being radiated from the devices around them. Due to this inherent relationship between devices, it is imperative that designers consider EMC during the development process else risk poor compatibility with the environments that their product operates in.

The result of unintended interactions between devices can range from imperceptible to disastrous. An interrupted phone discussion is a minor annoyance but a passenger aircraft navigation system is critical and the potential result of poor EMC design could be injury or death. In today's modern world there are electronics everywhere which all emit invisible electromagnetic energy. It's only through good design and testing that this has been achieved with few unintended interactions.

Radio Spectrum Management (RSM) is the governing body which regulates EMC products in New Zealand.

Why should you concern yourself with EMC?

In short, because it is a legal requirement [1].

All markets have laws and regulations which govern how electronic products interact with the environments around them. There are often tests which are mandated by these regulations which have to be done before the device can be sold in that market. There are 'Standards' documents which define all the tests a device must pass in order to prove compliance with the regulations [2]. Devices which fail any of these tests would then be disallowed from being sold in that market until it is modified or fixed so that it passes the tests.

You could have both an amazing product and customers lined up but if you can't prove it's compliant with the EMC regulations of that market, you won't be able to sell a single unit [3]. Concerning yourself with EMC during the development process reduces risk and the liability of a product with poor EMC.

What is EMC testing?

To prove that your device is compliant you must have documentation which shows that the device has passed all the tests specified for that product category [4]. This documentation usually comes in the form of test reports produced by an independent test laboratory. These test laboratories are accredited by a governing body so that the test reports they produce can be recognised as proof of compliance.

There are two main categories of testing which can be done to measure the electromagnetic compatibility of a device. The most commonly required category is 'Emissions' testing which measures how much energy the device radiates or conducts out and compares this to set limits. The other main category of EMC testing is 'Immunity' testing where the device is put in prescribed electromagnetic environmental conditions to test it's susceptibility to electromagnetic phenomena it may experience in the real world.

Emissions Testing

Emissions testing typically measures how much energy the device emits with the following modes:

- Radiated Radio-frequency (RF) Fields - Radiated RF fields are electromagnetic disturbances caused by the electrical activity in a device, and radiated out through the air.

- Conducted RF Noise - Conducted RF emissions are also electromagnetic disturbances caused by the electrical activity, but are conducted out along its cables.

- Magnetic or Electric Fields - Electrical activity in a device can produce magnetic or electric fields which can have near-field effects. Fluctuating voltages or currents in one device can induce or couple unwanted voltages or currents in other nearby devices.

The image below [5] shows various RF antennas used to measure the radiated RF fields of an electronic device:

Immunity Testing

These tests cover a range of situations where the device is put under 'worst-case scenario' conditions to see if its performance is affected. Testing your device for susceptibility can go a long way to ensuring that it will operate as designed in the environmental conditions it is likely to experience. Immunity testing typically seeks to measure the susceptibility of a device under the following conditions:

- Radiated RF Fields - Same as described in emissions testing but now the device is made to operate under a barrage of RF noise from an external source. The conductors in that device can act like an ‘accidental receiving antenna’ and absorb part of that RF energy.

- Conducted RF Noise - Same as described in emissions testing but now the noise is in injected into the devices cabling.

- Transients - Surges, lightning strikes, and switching noise from electric motors can induce high voltage transients onto the cables which supply your device. These transient pulses could cause permanent damage to your device if not designed for properly. These transients are artificially induced into the cabling to test its effect.

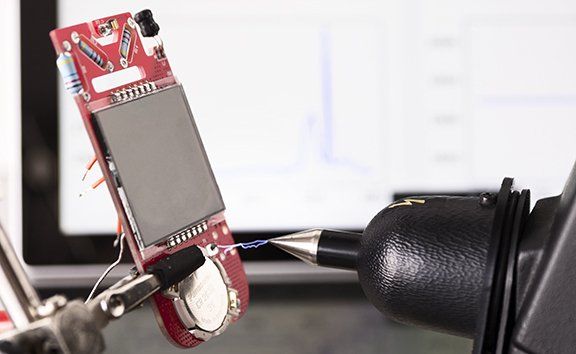

- Electrostatic Discharges (ESD) - Lightning strikes or even humans can cause electrostatic discharges to harm your device. Surfaces which can be touched by a user are subjected to prescribed ESD events (read 'sparks') and then tested to ensure no loss of functionality can occured.

The image below shows ESD validation testing we did at Beta Solutions, prior to sending a device to an accredited test laboratory for final testing:

What can be done to ensure that my product passes EMC testing?

Failing EMC testing can be very expensive. Not only because the cost of redoing testing, but there is the additional R&D cost associated with the redesign time and the opportunity cost of a delayed product launch. So naturally investing time in designing for EMC early on in the product development process can pay dividends if your device then passes EMC testing first time.

Understanding and predicting how electronic components interact so that they can be designed to pass EMC testing is a tremendously complex task. As such, it is impossible to ensure with 100% certainty that a product design will not fail EMC testing each time it is sent to the lab. Here are some principles which we apply to our projects to reduce the probability of EMC test failures:

- Use good EMC practices - Our engineers have years of experience and training which enables issues to be remedied before they become problems. We achieve this by:

- Having a sound understanding of EMC principles

- Over-design (safety factors)

- Using known 'good' designs

- Applying industry accepted 'rules of thumb'

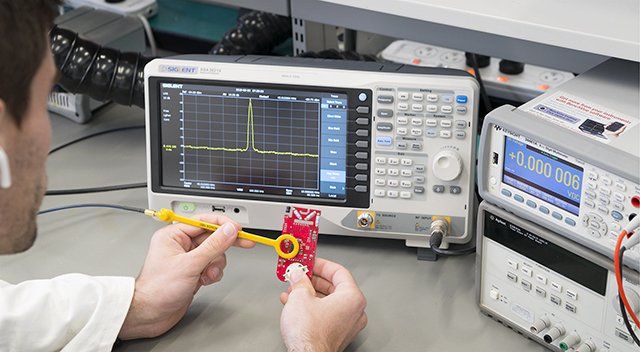

- Test early, test often - There are more solutions avaliable if issues are found earlier in the development process. Hence the need to test early and often so that these issues can be found and then remedied when the cost implications of design changes are the least. At Beta Solutions we have specialised tools in our lab which allow us to do limited pre-compliance testing so we can have more confidence that a device is compliant before it is sent away for testing.

- Use Computer Aided Design (CAD) Tools - Using computer tools to model electronic circuits for running simulations can be powerful for validating designs before they've even been prototyped. Changing a computer model of a circuit takes significantly less time than changing a prototype.

The image below shows a Beta Solutions Engineer scanning a device for sources of RF emissions with our spectrum analyzer and a near field probe:

Conclusions

The legal requirement for EMC compliance is here to stay. Every electronic product sold in New Zealand must comply. Embrace it now to minimise liability and ensure that your new product is a success.

Designing for EMC can be a tremendously complex area, often requiring one to be familiar with hundreds (or thousands) of pages of EMC standards. Therefore, it is often prudent to use the services of a professional electronics design consulting firm to take the burden off you.

To reduce the probability of EMC non-compliance, we at Beta Solutions, consider the implications for EMC compliance with every decision. We aim to design our clients' electronic products so that they pass the EMC testing process first time. Beta Solutions has years of experience with complying with standards which enables us to create products which do not cause interference and are immune to their environments.

If you would like to know more about EMC compliance in electronics product development, feel free to get in touch via our contact page or give us a call.

References:

- Radiocommunications (EMC Standards) Notice 2015, Part 3 clause A, Retrieved from: https://gazette.govt.nz/notice/id/2015-go4671

- Ministry of Business, Innovation and Emplyment (NZ), 2017. Compliance standards for EMC & Radio. Retrieved from

https://www.rsm.govt.nz/compliance/supplier-requirements/compliance-standards-for-emc-radio

- Radiocommunications Regulations 2001, Clause 37.1.a.ii, Retrieved from: http://www.legislation.govt.nz/regulation/public/2001/0240/latest/DLM71584.html

- Ministry of Business, Innovation and Emplyment (NZ), 2014. Product documentation. Retrieved from https://www.rsm.govt.nz/compliance/supplier-requirements/product-documentation

- Schneider Electric. Retrieved from https://blog.schneider-electric.com/telecommunications/2014/01/14/emc-standards-review-requirements/