These PCB manufacturing services range from small volume pre-production units, to facilitating the entire high volume production process.

Our in-house ability to manufacture small batch sizes ensures rapid turnaround time, whilst saving our clients from having to make large volume commitments. Often, our clients also turn to us for ongoing high volume outsourced manufacturing of their products. Beta Solutions' trusted network of national and international ISO9001 suppliers ensures on-time delivery and quality control of your product.

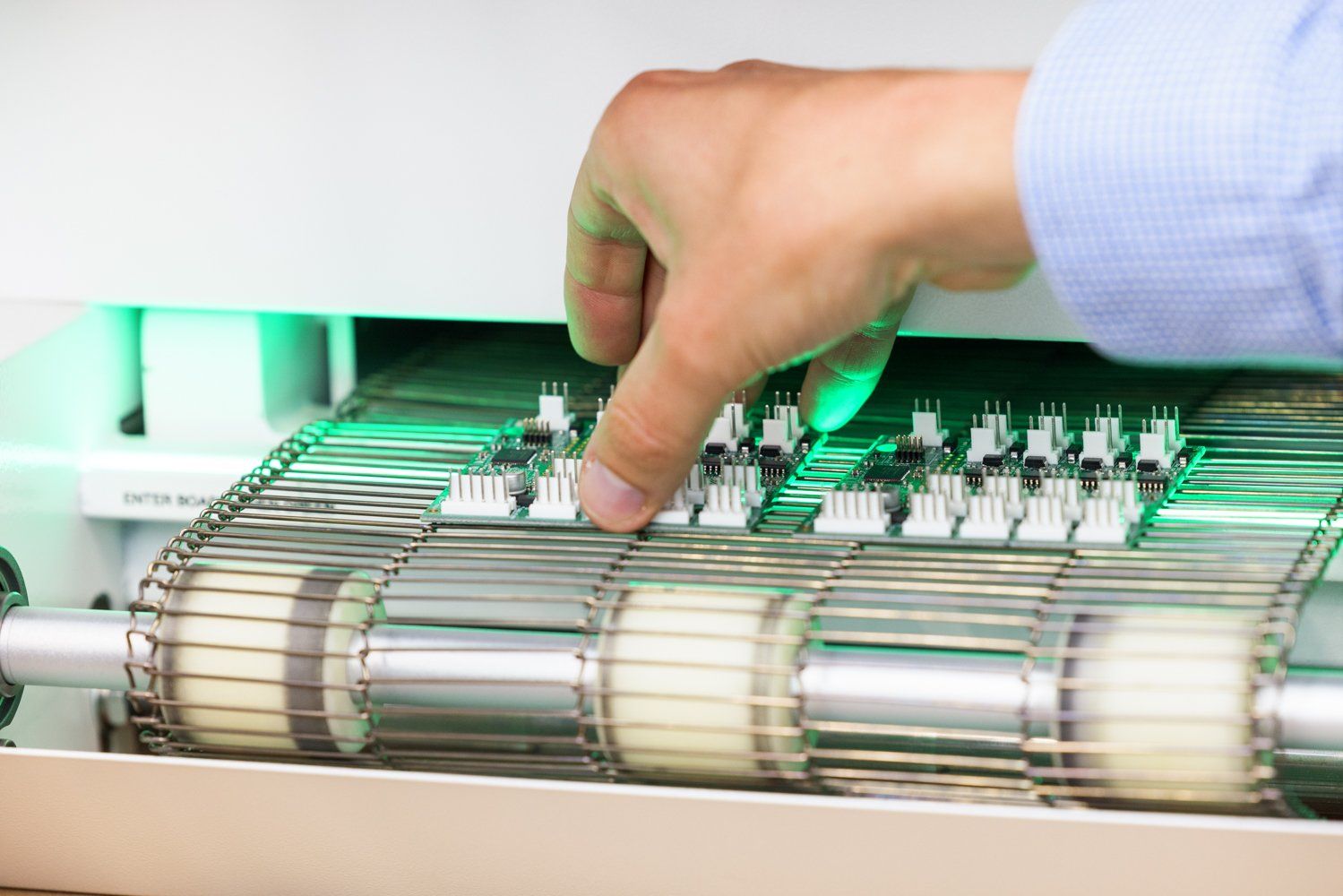

Production Manufacturing Services

Our electronics production manufacturing and pre-production services include:

- In-house low-vol production

- Outsourced high-vol production

- Final PCB assembly

- Validation and testing

- Quality control

Production Manufacturing Capabilities

Years of experience, in-house technical resources, a trusted network of local and international suppliers, and robust quality management processes have resulted in our electronic product manufacturing capabilities:

- Low Volume Production

- In-house low volume production

- Low setup costs

- Rapid turnaround time

- High Volume Production

- Outsourced high volume production

- ISO9001 accredited manufacturers

- Start to end facilitation

- Final Assembly and Testing

- Firmware programming

- Quality control testing

- Component database management

Production Manufacturing Projects

The following projects illustrate how our electronics and PCB production manufacturing services are resulting in commercial success for our clients: