The Wonder Project - Educational Power Meter

Engineering New Zealand is a non-profit membership organisation dedicated to promoting the interests of engineers and engineering.

The Wonder Project is Engineering New Zealand's initiative to get the next generation excited about a career in science, technology, engineering and maths (STEM). It’s about sparking wonder in STEM from a young age, building confidence, and having all young Kiwis believing they can achieve remarkable things.

The Power Challenge is for students years 7-8. With help from their teacher and a Wonder Project Ambassador, students discover the amazing phenomenon of electricity and renewable energy.

The Opportunity

Engineering New Zealand approached Beta Solutions to design a product which could “Light up a mini town with alternative energy power sources”.

The requirements were:

- LED lights (representing a mini town) needed to light up to indicate how much power was being produced.

- The sources of power needed to be wind and solar.

- The students needed to create and build their own wind 'turbine' blades.

- The entire unit needed to run entirely on the generated power - no external power sources!

- The unit cost needed to be within budget.

The Solution

While commercial toy wind generators existed, they ultimately did not fulfil the requirements. Perhaps most importantly, there were no off-the-shelf LED systems that could be calibrated to two different styles of power input, such as solar and wind.

Therefore, it was apparent that a custom electronics solution was needed.

Power Generation Design Aspects

For Solar power generation, a standard off-the-shelf product was used.

Creating a suitable solution for wind power generation presented more complexity. The most straightforward and cost-effective method entailed using a small electric motor. This motor, when operated in "reverse", essentially functioned as a generator, with the rotation of the motor shaft producing voltage and current.

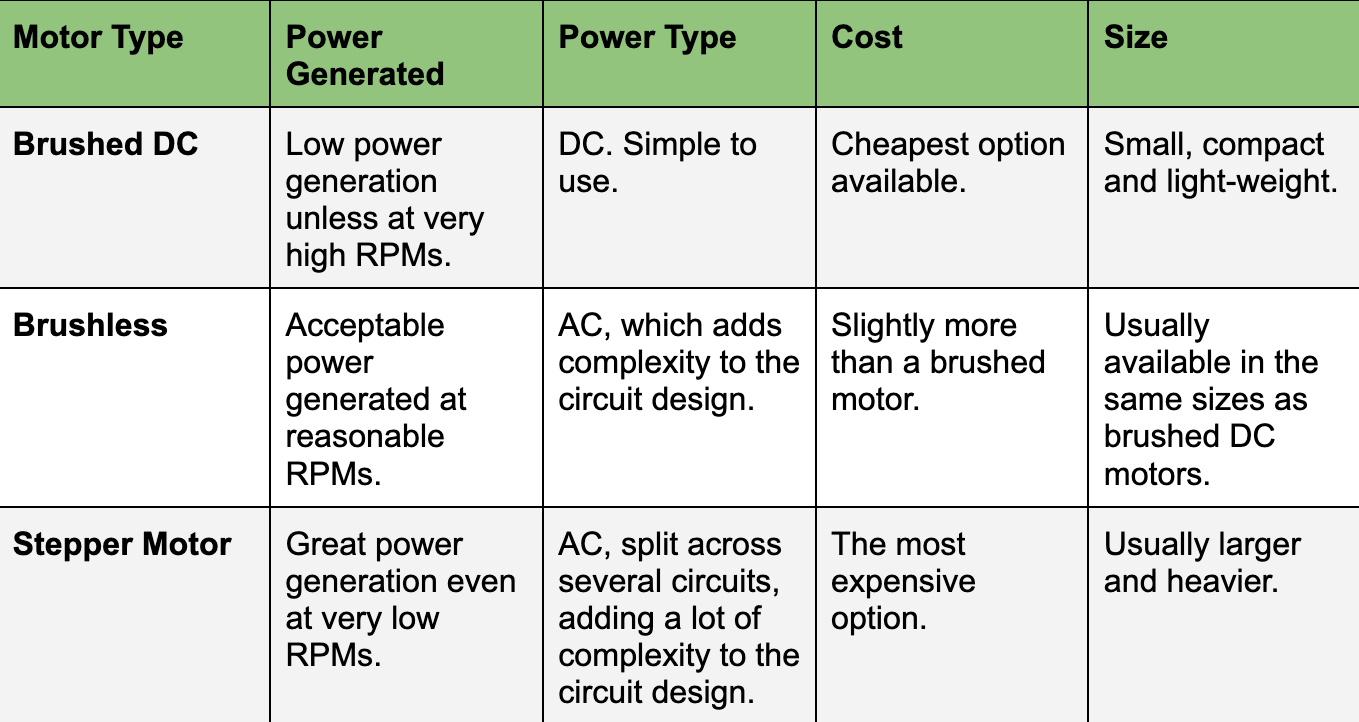

Regarding electric motors/generators, a variety of options were available for selection, each presenting unique benefits as shown in the table below:

Testing of the Brushed DC Motors ruled them out - as the wattage was too low to power multiple LEDs at the expected RPM of the wind generator.

However, tests with Brushless Motors were successful, ultimately producing enough power at the correct RPM. (The success of these tests rendered the need for more expensive and larger stepper motors unnecessary.)

Electronic Design Aspects

The blueprint of the circuit was planned with the key objective to sequentially illuminate multiple LEDs as the system's power output progressively increased.

Various designs were initially conceived; the superior models were then simulated and, following successful results, incorporated into both an operational prototype and eventually, the final product.

NB: The chosen circuit design employed a Charge Pump, which served to rectify and boost the voltage generated by the wind system. The combined voltage from both the solar and wind systems was then channelled into a sequence comparator. In this arrangement, the circuit allowed energy to be distributed through various branches, leading to the intended illumination of specific LEDs.

Mechanical Design Aspects

Navigating the constraints of a limited budget, while ensuring a sturdy design and providing a customizable experience for the students, presented its own set of complexities and challenges.

A wooden base, a wooden dowel pole, and a 3D printed motor bracket were crafted and tested as prototypes. The positive results of these tests determined the adoption of this design as the final construction choice.

Furthermore, a propeller hub design was conceived and brought to life through 3D printing. This design allowed students to attach up to 16 popsicle sticks to it. As such, students could engage in the personal creation of their blades or aerofoils using these popsicle sticks, adding a layer of customization and hands-on involvement to the learning process.

Production

Upon final acceptance testing of the prototypes, all the various components (electronics and mechanical aspects) were put into Volume Production.

Beta Solutions managed the supply chain logistics, ensuring on time delivery of the kits before the (required) start of the school term.

Success

The positive response from students to these kits emphasized their value in teaching complex concepts. They offered a tangible, hands-on understanding of power generation, aligning well with the principles of STEM education.

As the goal of the program shifts towards broadening its influence and penetration, the central focus now is on refining the production process for greater efficiency, and where feasible, further reducing the per-unit cost.

Client Testimonial

"Beta Solutions have become the tech arm of our team, enabling us to deliver a custom product to schools which we can rely on. They’ve been supportive from the start, working collaboratively with us, to develop our ideas into a product we can be proud of."

Shelley Pearce - Wonder Project Director

* All the content in this article, including imagery, has been approved by our client for publication on this website.