Electronic Reaction Game Table

Introduction

Our client, Pyro Ltd, had been engaged by their client to supply an “out of the ordinary” bar leaner. Pyro's idea was to embed a two player reaction game directly into the table - which would test the player's reaction by sensing who could hit the correct button the fastest.

To make the game even more engaging, the slower/losing player would receive a (mild) electric shock!

At the time when Pyro approached Beta Solutions, they had fabricated the table and had developed some prototype electronics.

Our brief for this project was to re-develop the electronics hardware and firmware into a fully “player-ready” (ie: Ruggedised) version as fast as possible.

Development Approach

Technical Background:

The table incorporated four sets of buttons and LEDs for each player.

- The LEDs were programmable RGB LEDs so different colours could be used for the user interface, and to differentiate game modes.

NB: There was also a game mode which replaced the electric shock function, with a buzzer sound - for those who are not-so-shock-tolerant! - Each ‘button’ input was actually a set of two buttons - with metal casings - that the user would have to push

simultaneously

for the input to be valid. This was done to ensure that there was a complete path for the electric shock outputs.

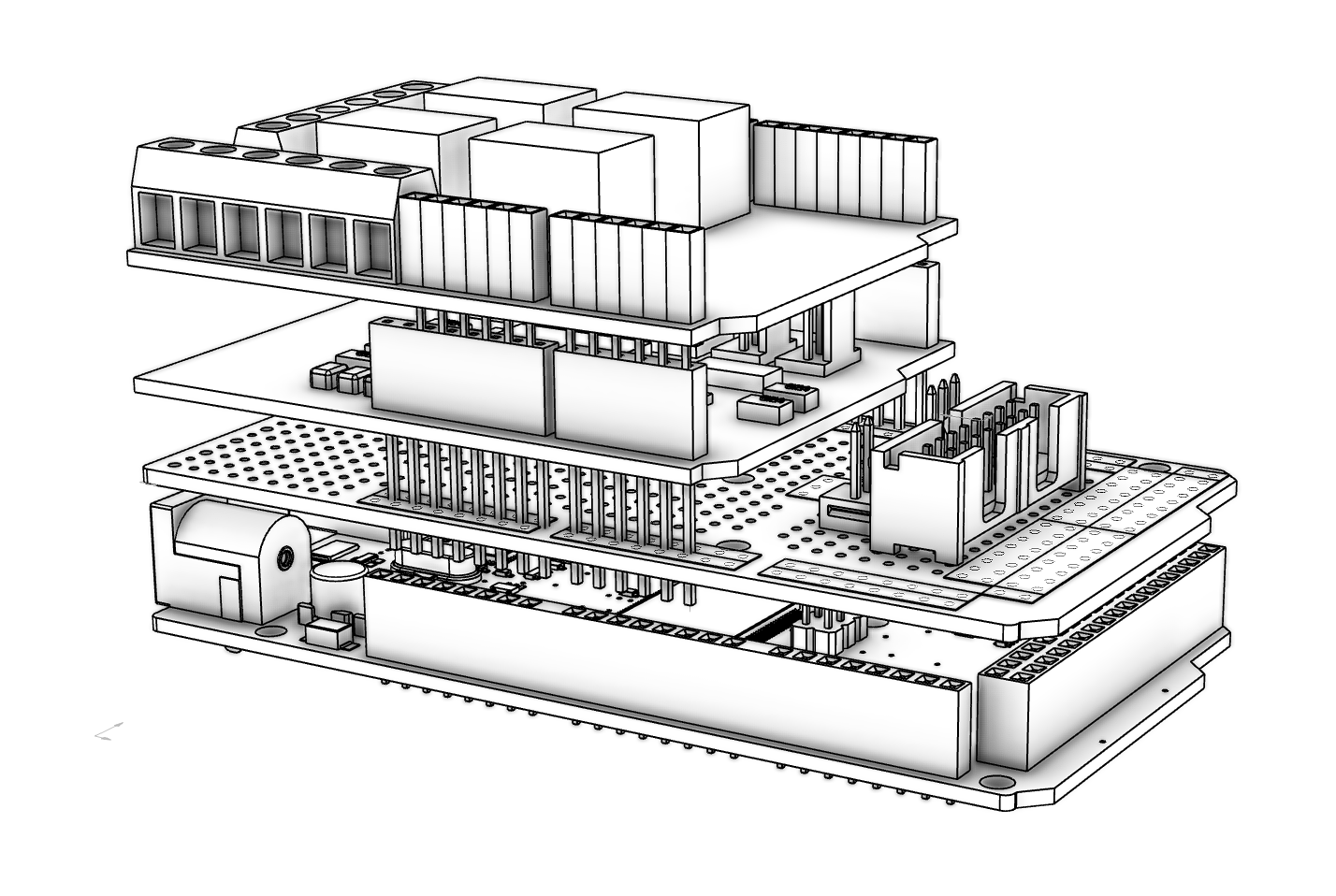

Architecture:

Given the tight timelines, we worked with the client to devise an approach which would result in the best possible outcome.

At all times, decisions were made to balance: Cost vs Timeframes vs Scope (a.k.a: The Project Triangle.)

Time was spent in the early stages of the project devising the optimum product architecture. Some of these key architecture decisions are outlined as follows:

1. Use of Commercial Off The Shelf components

While custom designing electronics hardware often is the way to go - especially when the product is expected to be produced in volume - given the one-off nature of this project, we opted to use Commercial Off-The-Shelf (COTS) components for

certain aspects.

NB: Using COTS components can be an ideal solution for one-off products, due to the following reasons:

- It can lower risk, as the COTS components have already been validated

- It can therefore reduce time-to-market

- It can therefore lower cost, as design cost is usually more expensive just purchasing something off-the-shelf.

For this particular project, it was chosen to use the following COTS components:

- Electric shocker

Several COTS devices were evaluated and one was chosen based on its ability to (i) integrate with the existing hardware and (ii) which could easily be used to “trigger” the electric shock. - Tactile switches

Capacitive and light-based solutions were all evaluated as options for the buttons. However, it was deemed that tactile switches would be the optimum approach due to lowering risk, cost and timeframes. - Microprocessor

While there are a plethora of microprocessors on the market, a COTS microprocessor solution was chosen that would again lower the risk, cost and timeframe. In this particular case, it was opted to use a development board for a 32-bit Infineon PSoC™ 5 microcontroller.

2. Use of proven Firmware Framework:

While the hardware was chosen to largely utilise proven COTS components, the firmware still needed to be custom designed.

In order to lower risk, time and cost, we selected a firmware framework that was proven and one in which Beta Solutions has extensive experience with.

This approach enabled commercial-ready firmware to be written and tested in a considerably short time frame.

The final result was an engaging reaction game table and a satisfied customer.