Innovating the Future of Water Heating: Rinnai Unleashes HydraHeat™

(Photo credit: Rinnai)

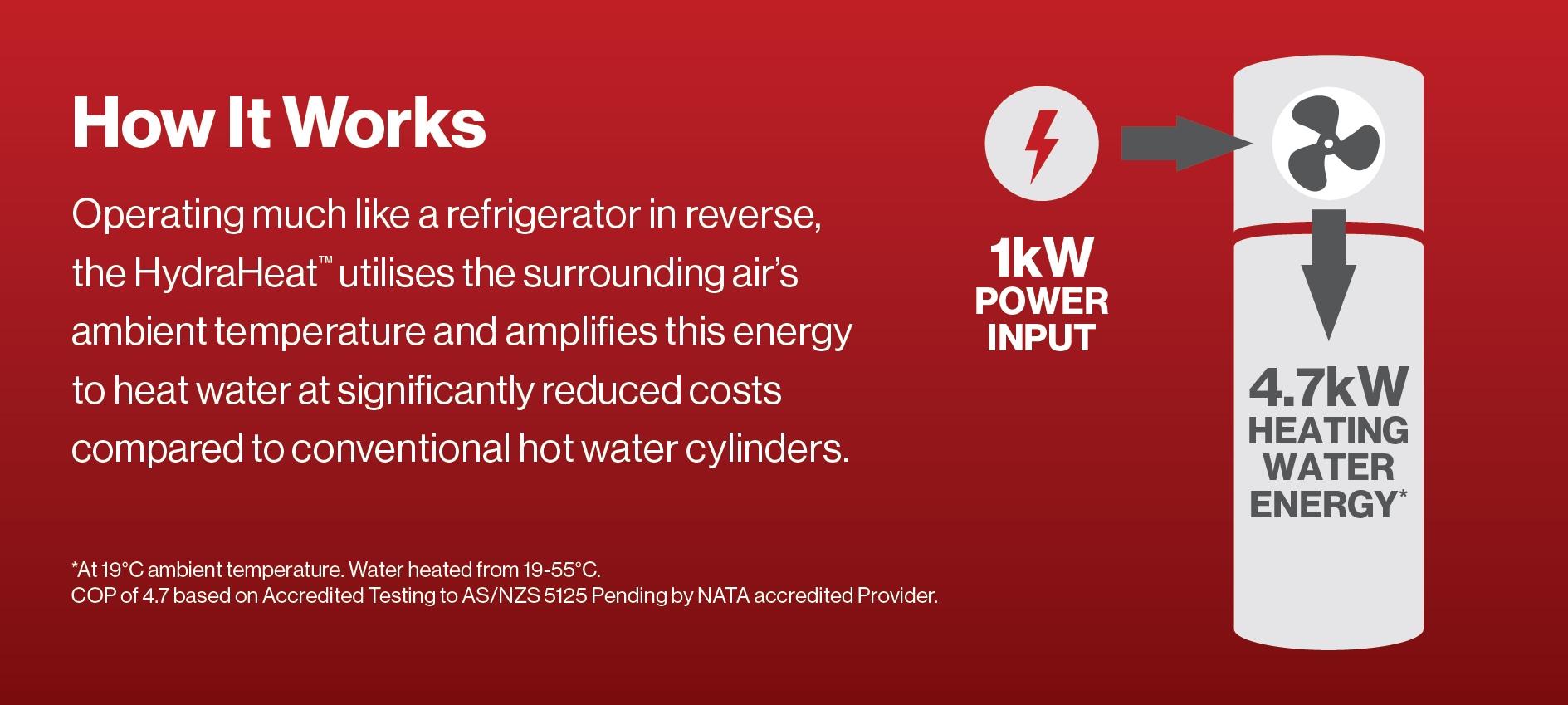

Rinnai is synonymous with innovative heating solutions, providing customers with advanced technology designed for efficiency and reliability. As they ventured into their new project - the HydraHeat™ Hot Water Heat Pump - Rinnai turned to our expertise to develop an electronic control system refined for performance. We worked closely with Rinnai to create a control system harnessing the efficiency of heat pump technology, with estimations of up to 75% savings on hot water costs*.

Opportunity

Rinnai's HydraHeat™ represents the evolution of water heating solutions, integrating heat pump technology with traditional hot water systems for enhanced energy efficiency. Recognizing the potential of this technology, Rinnai required a state-of-the-art electronic control system. The goal was not only to control the heat pump efficiently but also to ensure user safety, compliance with regulatory standards, and ease of use.

Challenges

Creating an electronic control system for a highly efficient heat pump hot water cylinder introduced several challenges, including:

- Design of a PCB controller that manages both low and high-power components while maintaining electrical isolation for user safety.

- Development of robust firmware capable of executing heat pump control, fault monitoring and reporting, and user interface management.

- Incorporating features like Real Time Clock (RTC) with a backup battery, buzzer, flash storage, and debug LEDs.

- Ensuring the system met stringent compliance standards for electrical safety, radio compliance, and EMC.

Solution

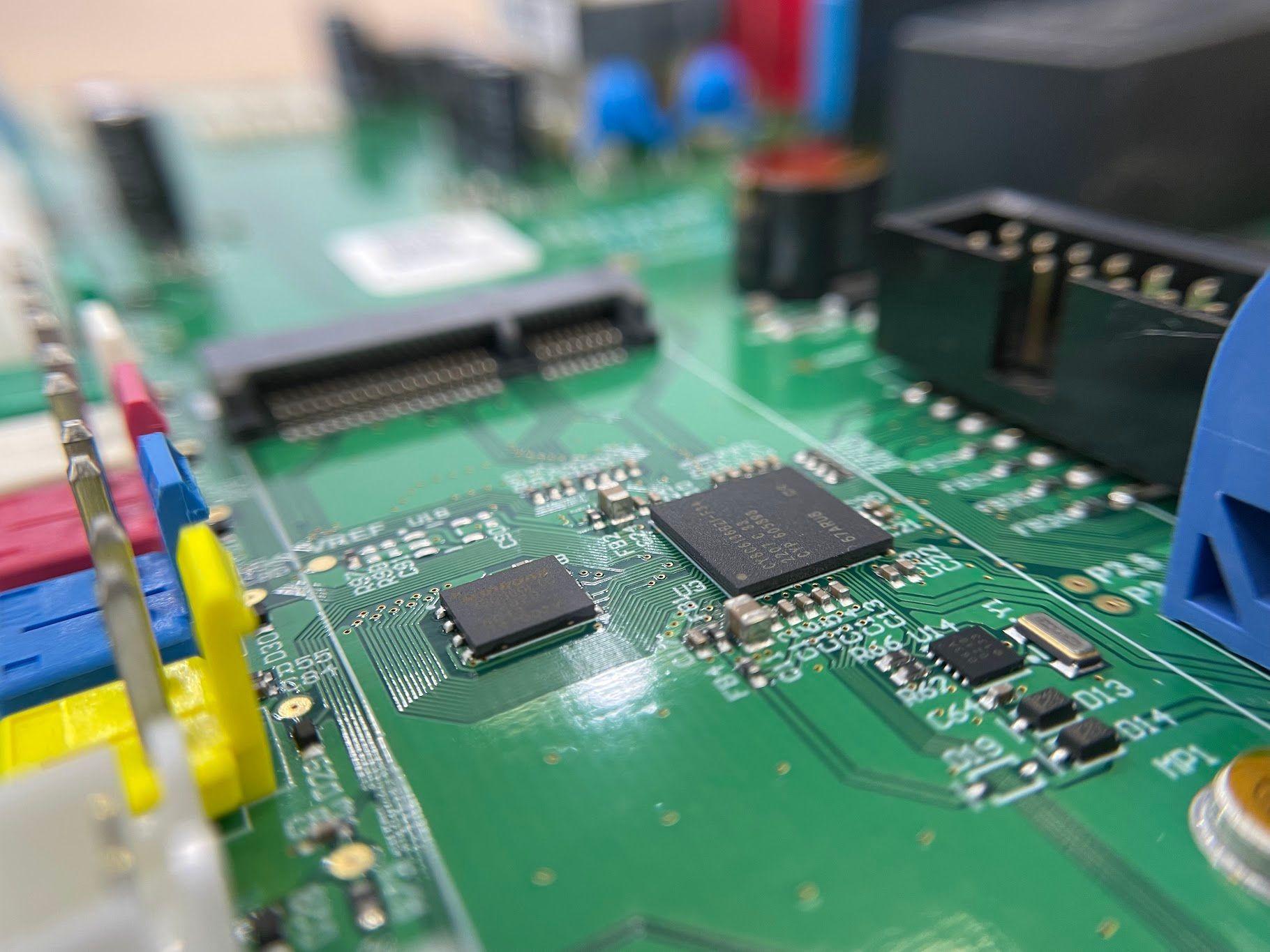

Our innovative design solution addressed Rinnai's requirements and included the following key features:

- A mixed-signal embedded microprocessor running custom firmware for complete system control.

- RTC and backup battery to maintain system timing and schedules during power outages.

- A buzzer for auditory alerts and flash storage for data retention.

- Debug LEDs for straightforward diagnostics.

- High power brushless motor controller with feedback for the compressor unit.

- RS485 communication protocol for robust serial data transmission.

- An OLED display and capacitive touch buttons for intuitive user interaction and system setup.

- Isolated mains power supply to power the controller safely and efficiently.

- Integrated power and voltage monitor for real-time energy monitoring of the mains electricity supply.

- Relays to manage power to the compressor, backup heater, and reversing valve for precise control of heating and cooling cycles.

- A stepper motor controller to manipulate the electronic expansion valve accurately.

Firmware Development

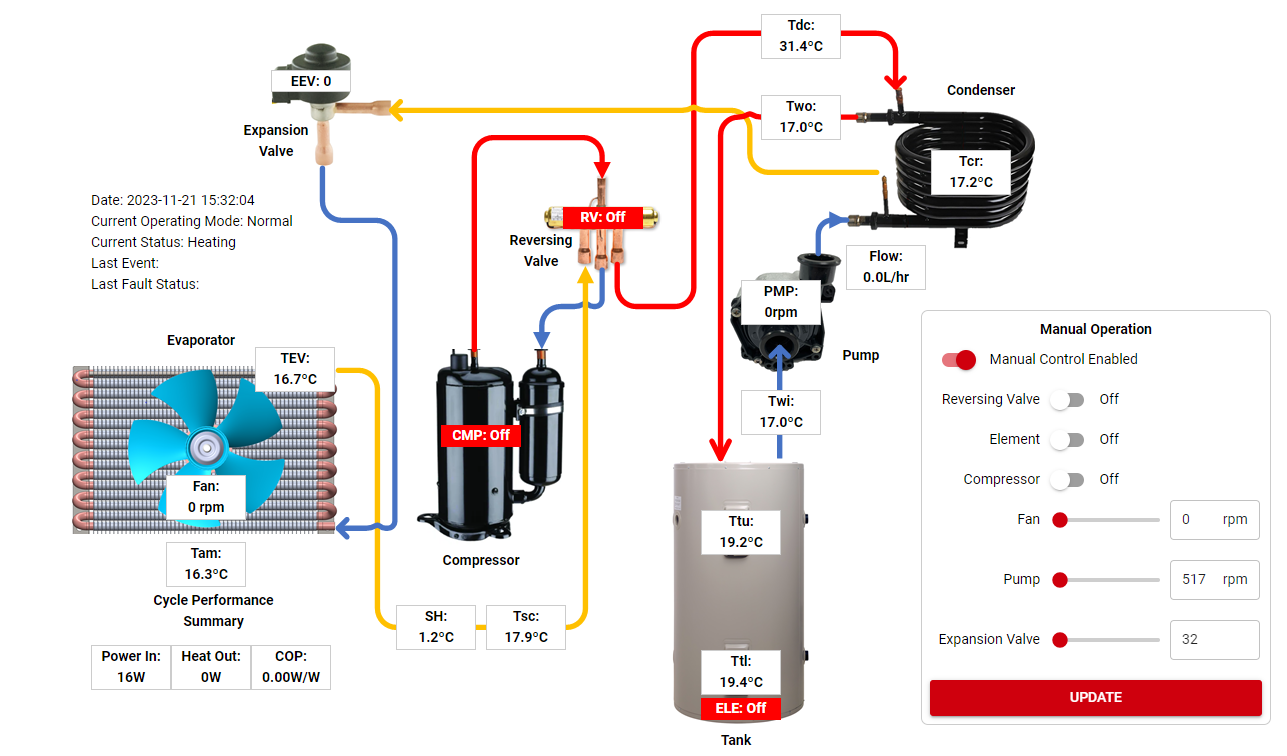

HydraHeat™is controlled by firmware developed with the following features for optimal performance:

- Accurate temperature monitoring for consistent system regulation.

- Sophisticated algorithms for an efficient heating control loop, optimizing heat output while reducing energy consumption.

- Customizable user settings include "High Usage" modes with additional electric heating and "Eco" modes for energy-saving operation.

- User-friendly interface with an LCD display and capacitive buttons for simple adjustments of settings, timers, and operational modes.

- Built-in frost protection and defrosting mechanisms, making the heat pump adaptable to various outdoor climates.

- Integrated diagnostics to identify issues, safely power down the equipment, and alert users to any problems.

- Event, state, and diagnostic data recording to local memory for detailed analyses of any malfunctions by service personnel.

- Firmware updates can be applied via USB, with encryption in place to protect Rinnai's intellectual property.

(Photo credit: Rinnai Website)

Technician App

To provide a comprehensive monitoring and maintenance tool for the HydraHeat systems, we designed a specialized Technician's Interface Application. This Windows-based program, once installed on a technician's PC, allows for a direct connection to the HydraHeat system via a USB cable. The intuitive application facilitates not only the monitoring of system performance but also provides capabilities for firmware upgrades and fault diagnostics, ensuring HydraHeat operates at peak efficiency and reliability.

Certification and Compliance

We managed the compliance testing phases, ensuring the HydraHeat™ met all required standards for electrical safety, EMC, and radio compliance. This comprehensive testing guaranteed the system's reliability and safety, clearing it for consumer use.

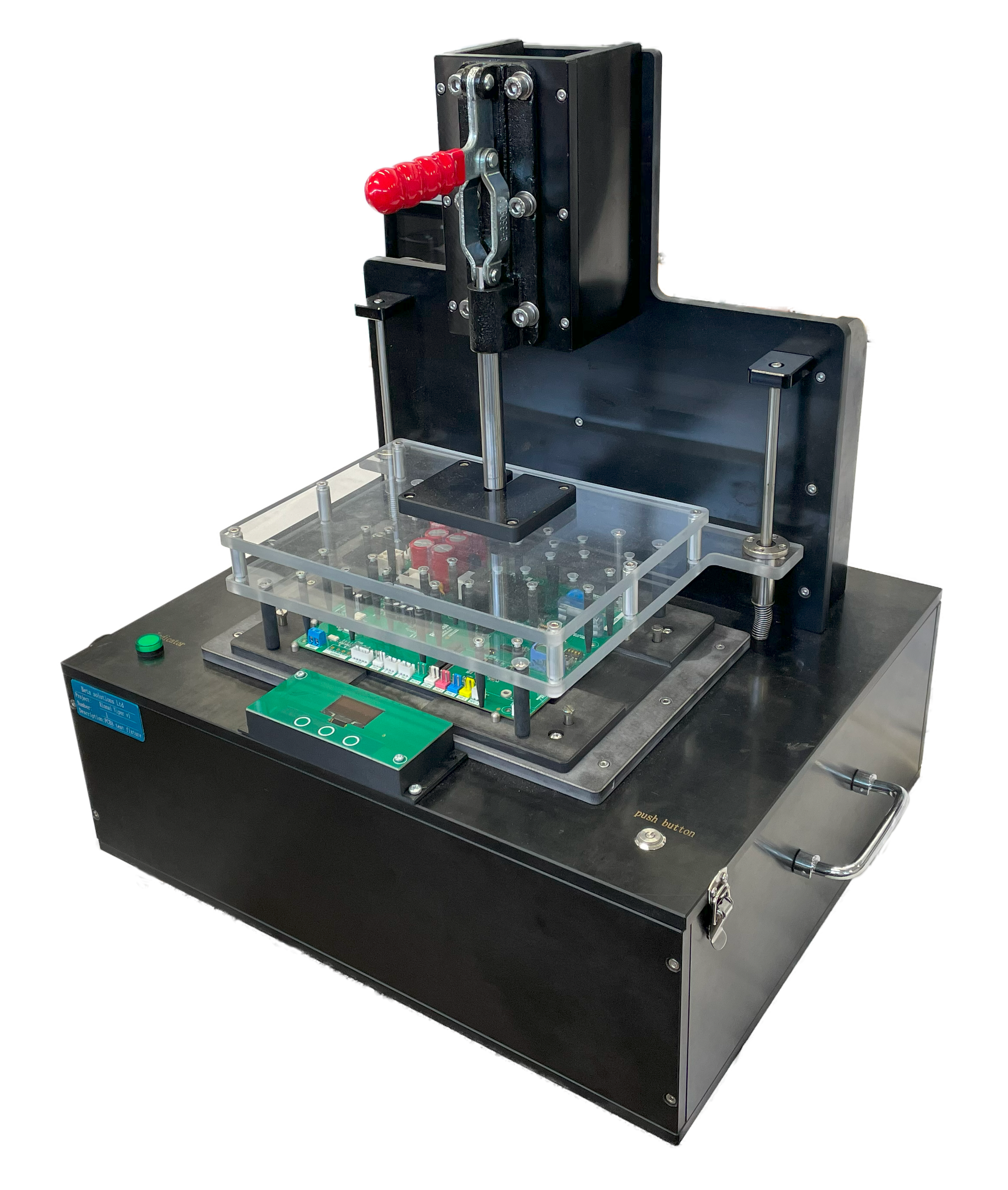

Production Quality through Automated Test Fixture

To ensure consistent quality during the production of the HydraHeat™ control systems, we developed an automated test fixture equipped with custom test software. This fixture is essential for methodically checking and verifying each PCB as it comes off the manufacturing line. The test software runs through a comprehensive set of functional tests and records the outcomes for quality control purposes.

The fixture's user interface is straightforward, enabling technicians to execute the test sequences quickly and effectively. In just a few minutes, the fixture can complete the full spectrum of necessary tests for these complex electronic boards. The results are logged for ongoing production quality analysis, and each board is imprinted with a unique serial number to provide trackability.

The test fixture uses a bed of nails method for making contact with designated test points on the PCBs. This setup, though sophisticated in its implementation, allows for rigorous quality assurance checks within the production environment. By integrating this testing procedure, we ensure that every HydraHeat™ control system delivered to Rinnai is reliable and meets the stringent quality standards expected by both us and the customer.

Success

Our collaboration with Rinnai yielded the control system for their innovative HydraHeat™ product, a testament to innovative engineering and user-centric design. This venture has positioned Rinnai's new heat pump hot water cylinder as a future-proof solution for sustainable living. The HydraHeat™, which was recently launched, promises eco-friendly efficiency for everyday homes, signaling Rinnai's commitment to greener solutions and energy savings of up to 75% on hot water costs.

* All the content in this article, including imagery, has been approved by Rinnai for publication.

Photos sourced from:

- https://rinnai.co.nz/water-heating/hot-water-heat-pump/hot-water-heat-pump/hydraheat

- https://rinnai.co.nz/media/kzeikfq2/hydraheat-flyer-web-ver2.pdf

- https://rinnai.co.nz/media/lqcjd2zn/hydraheat-hwhp-op-guide-31115-a-v6.pdf

- https://rinnai.co.nz/media/ca4nezm1/31114-b-hydraheat-install-guide.pdf